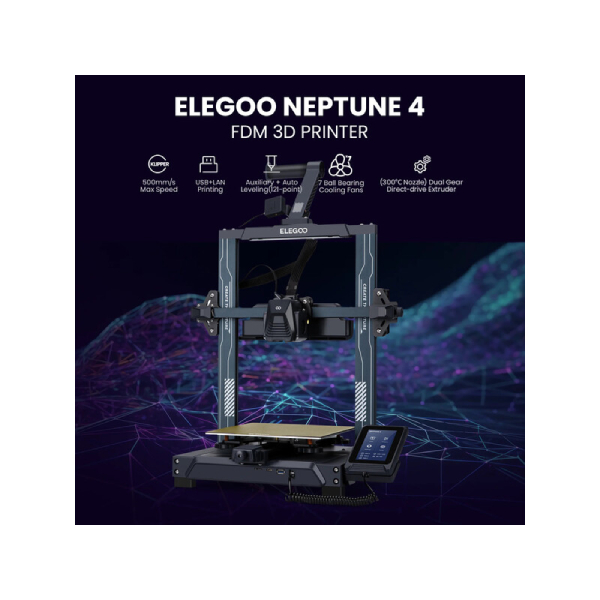

Technical Specifications

Technology

FDM (Fused Deposition Modeling)

Mainboard

Klipper ARM 64-bit Quad-core

LCD screen

4.3" Full Color HD Capacitive Screen

Connectivity

WLAN / USB

Power Requirements

100-120V/200-240V

Output Voltage

24V

Print precision

±0.1mm

Nozzle diameter

0.4mm

250W hotbed

Leveling Mode

Auto 121 points, Auto Bed Leveling or Manual

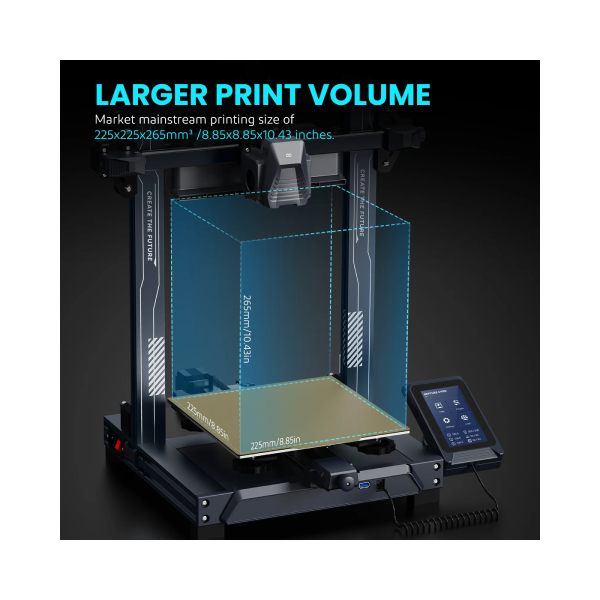

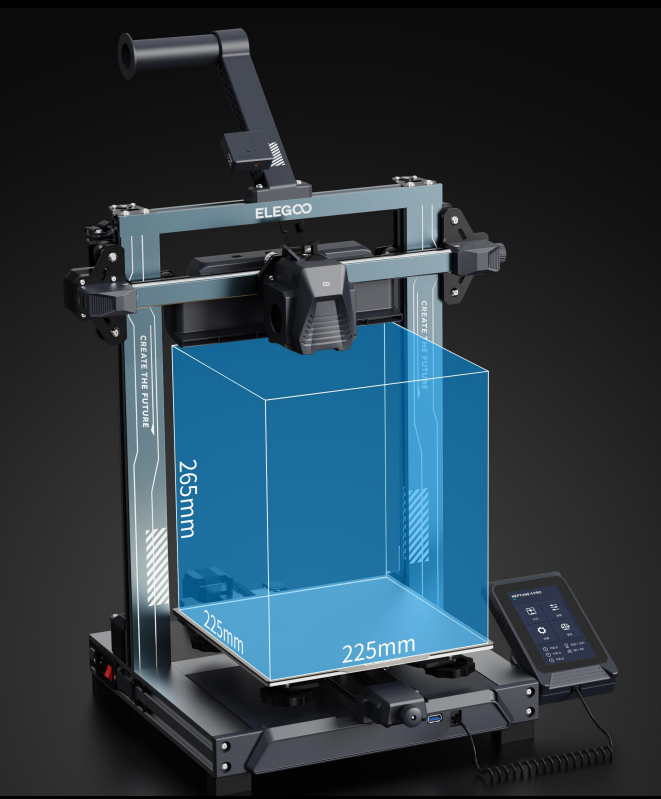

Build Volume

225mm(D) x 225mm(W) x 265mm(H)

Printing Speed

30-500mm/h (250mm/s is recommended)

Light Source

UV Integrated Light (wavelength 405nm)

Compatible Filaments

PLA, ABS, TPU, PETG, Nylon

Input Formats

STL, OBJ

Output Formats

Gcode

Slicing Software

Cura

General Specifications

Pre-installed Klipper Firmware

It features a quiet Klipper motherboard and ARM 64-bit 1.5G main frequency quad-core processor for sufficient processing power

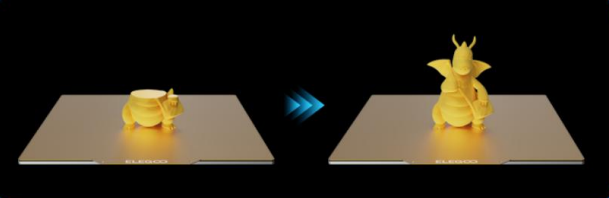

It prints at a amazing speed of up to 500mm/s recommended 250mm/s

Supports advanced functions like input shaping and pressure advance to achieve accurate and smooth models

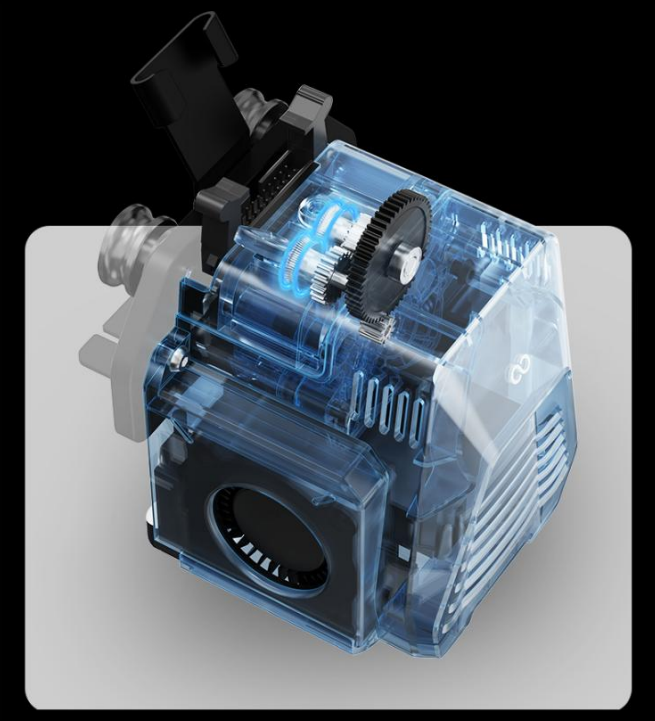

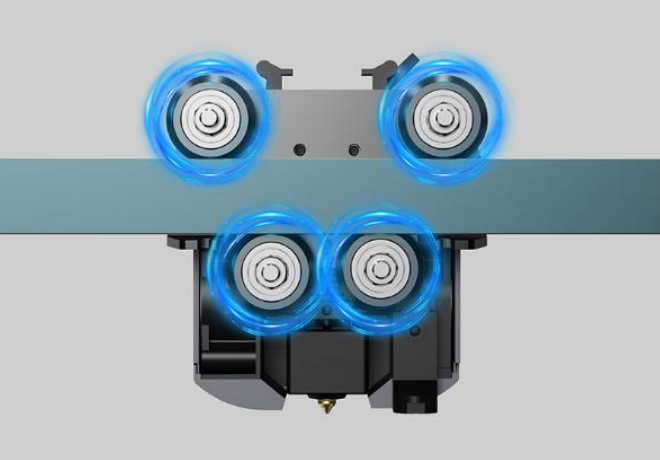

Dual-Gear Direct Extruder

The dual-gear direct drive extruder with gears made of SUS303 stainless steel features adjustable extrusion force and a 5.2:1 reduction ratio

Which ensures smoother filament feeding and stable accurate printing, greatly reducing nozzle clogging and gear jumping problems

Ideal for printing PLA, PETG, ABS, TPU and high-temperature filaments like Nylon

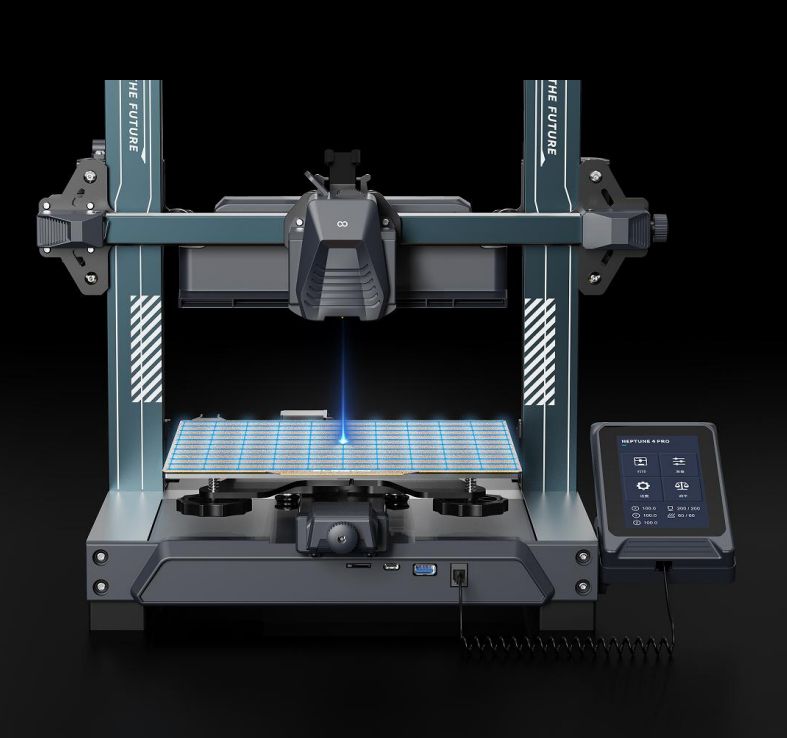

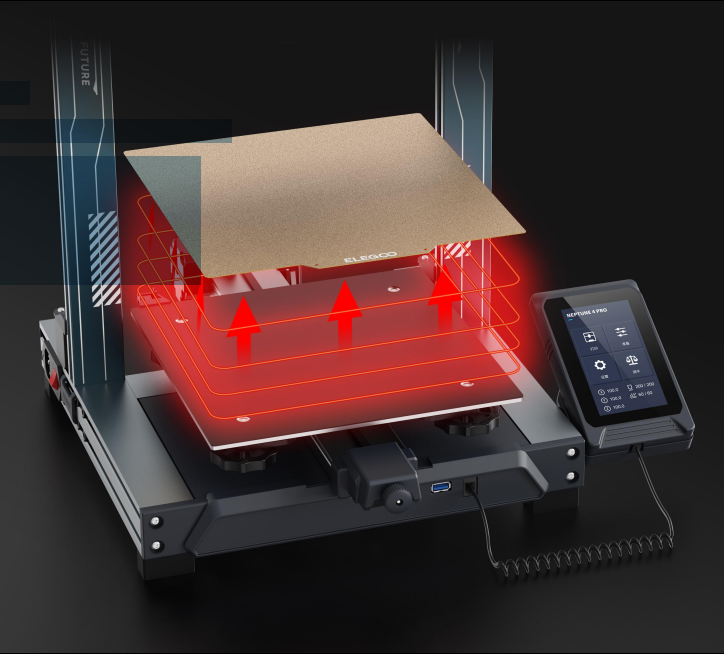

PEI Magnetic Platform

special coating and spring steel sheet for good adhesion and warping resistance

Easily removed or ejected by bending the print steel sheet

The 250W hotbed can quickly heat up to 110°C

Auto/Auxiliary Bed Leveling

The 121 11x11 points auto bed leveling ensures quick and accurate leveling of the build platform

You can achieve consistent and reliable prints every time without the need for manual bed leveling

Additionally, the auxiliary leveling by hand-twist knobs allows for further fine-tuning of the print beds level for improved print quality

300°C High-temp Nozzle

the printer can handle a wide range of filaments, including PLA, PETG, ABS, TPU and high-temperature filaments like Nylon

The extended hot end design ensures consistent heating and faster melting and extrusion, resulting in faster printing speed

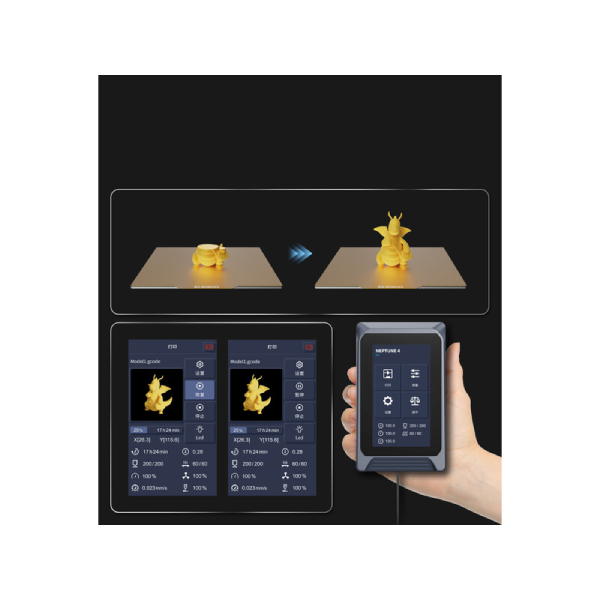

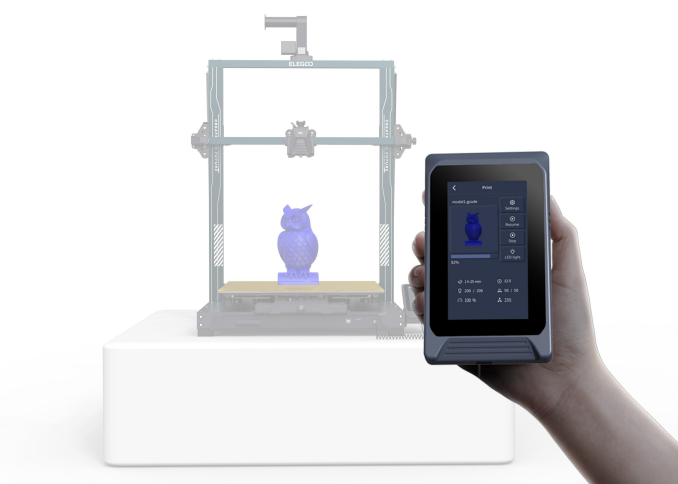

Removable Capacitive Touchscreen

The 4.3-inch removable magnetic capacitive touch screen can be operated by hand-held or fixed on the base,

With a print model preview function to preview the model image during printing and observe the printing progress, supporting multi-language

There also comes with a drawer toolbox on the machine base to store tools used by the printer such as Allen wrench and nozzle accessories

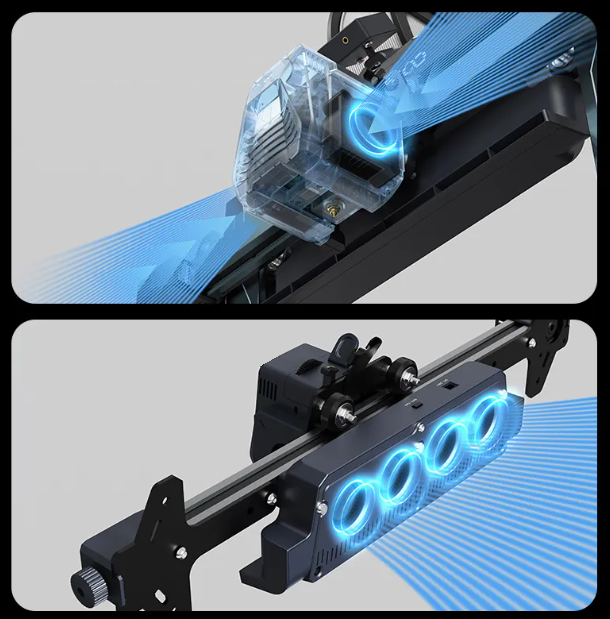

Efficient Heat Dissipation

Features 2 thickened double-sided 4015 ball bearing cooling fans

Features 4x4020 ball bearing blower fans behind the print head for omnidirectional rapid cooling

The newly printed layers to prevent warping and improve overall print quality even at a fast printing speed

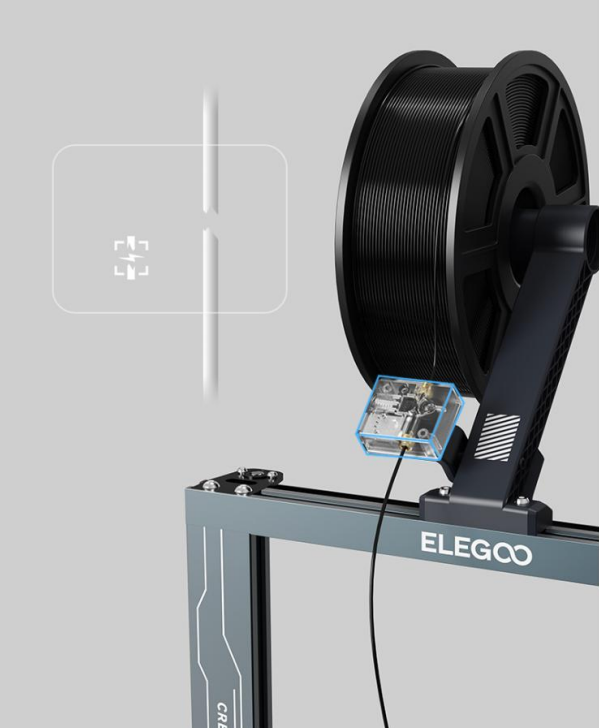

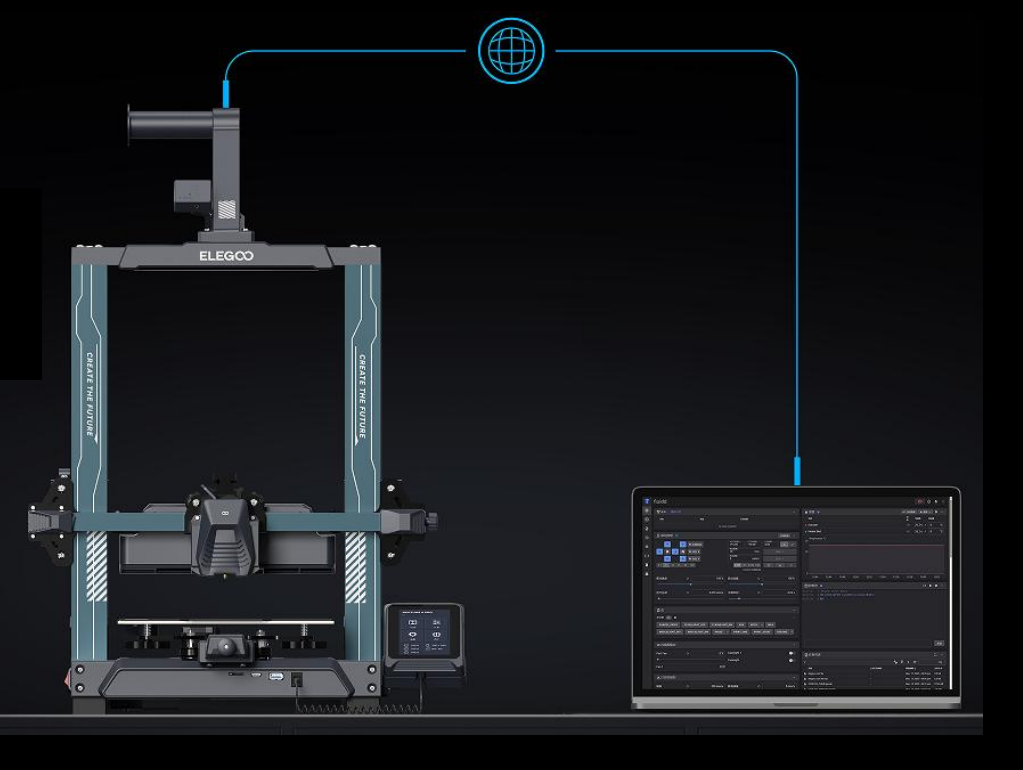

Supports LAN networking printing

You can use the WEB terminal to remote control and monitor your printer on the same network

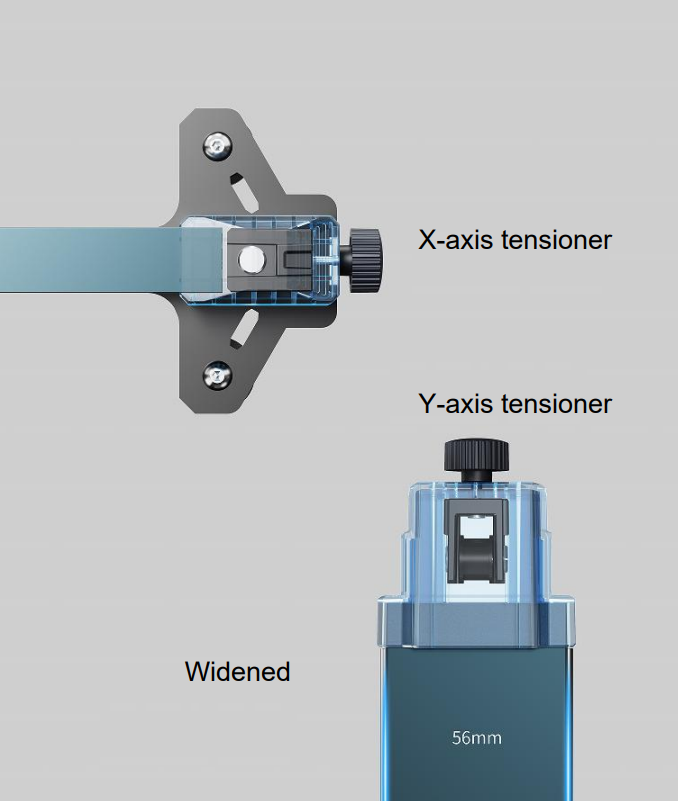

XY-axis Belt

Easy to adjust with a hand-twist knob, and the widened Y-axis profile ensures a stable printing platform

Model Preview

It features a printed model preview and a pause printing function to monitor printing progress and make adjustments as needed

The gantry LED light bar

Can be operated via the screens button for conveniently observing model printing in a dark environment

Nozzle LED light

Can be operated via the screens button for conveniently observing model printing in a dark environment